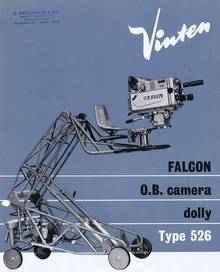

Ein früher mobiler O.B. Kamera Kran von 1964

Bill Vinten hatte Ideen und wollte für jeden Bedarf etwas anbieten. Und draußen "im Feld" konnte man den 1 Tonnen schweren HERON nicht mit sich rum schleppen. Da mußte etwas bewegliches her, der FALCON.

FALCON - outside broadcast (O.B.) camera dolly Type 526

The new Vinten Falcon O.B. Dolly is designed to offer the producer of outside broadcasts equal camera mounting facilities to those enjoyed by his counterpart in the studios.

Unlike the big heavy studio crane, however, the lightweight Falcon can be quickly dismantled into four main sections which allow it to be transported easily from studio to location, and handled in the difficult environment frequently encountered in outside broadcasting.

No power is needed from external sources to power the elevation of the crane-arm and the crew consists solely of a cameraman and a tracker.

Above all, the Falcon offers camera shots which were previously completely unobtainable with existing equipment and combines this feature with studio qualities of smoothness, silence and rigidity.

.

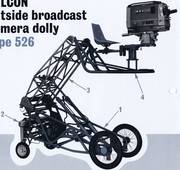

The structure is welded entirely from steel in the interests of strength and rigidity. It is designed for simple rapid dismantling and assembly to ease transport problems, and breaks down into four main assemblies, comprising:

- CHASSIS

- STEERING ASSEMBLY

- JIB ASSEMBLY

- PLATFORM ASSEMBLY

These separate main sections are shown below.

Chassis

The chassis is a tubular steel fabrication supported by four wheels, the rear pair being part of the Steering Assembly. The front wheels can be either 26 in. (65 cm) diameter pneumatic, 12 in. (30 cm) diameter pneumatic or 12 in. (30 cm) diameter solid tyred wheels. With the latter arrangement the dolly can be run in channel section rails, if required. A hand operated hydraulic pump and twin accumulators are bolted to the chassis.

Steering Assembly

The steering assembly is fixed to the rear frame members of the chassis. It consists of a strong housing containing a fully compensated Ackermann steering linkage between the hand bar in the centre and the two rear wheel king pins. The rear wheels are 12 in. (30cm) in diameter and can be solid tyred (for operation within channel section rails) or pneumatic. The rear wheels are fitted with internal expanding brakes operated by rod linkage from a brake lever mounted on the steering assembly. The brake lever has a ratchet enabling it to be used as a parking brake. The steering assembly is fitted to the chassis by four quick acting clamps.

Jib Assembly

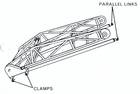

The jib assembly is a welded steel tubular fabrication which is pivoted at the rear to give a range of movement at the platform of 5 ft. 2 in. (154cm).

The main jib bearing is fixed to the chassis with four clamps and connected to the hydraulic rams with quick release Pip pins.

Platform Assembly

The platform frame is of fabricated steel tube supporting a robust steel column at the centre. On this is pivoted the mounting for the seat and the pan and tilt head which is capable of full 360 rotation.

The column has removable spacers 7 inches high, which give two camera height ranges. In the high range the camera head mounting platform can be elevated between 22 in. (55cm) and 7 ft. (2,13m). In the low range the maximum height is 6 ft. 5 in. (1,95m) and the minimum height 15 in. (3,81m). The platform assembly is supported at the end of the jib by a pivot shaft retained by Pip pins, while Pip pins are also used to connect the parallel linkage members to the platform frame.

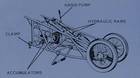

Hydraulic System

Energy is stored in two chassis-mounted accumulators charged with nitrogen under pressure. The hydraulic system includes the accumulators, two rams and a lever-operated hand pump in a closed circuit. By operating the hand pump the pressure in the system can be made exactly to neutralise the load of camera, cameraman, cable, etc. on the platform so that the jib and platform are maintained in a state of static balance. A rotary pump operated by a handle and mounted on the steering assembly, can then be used to raise or lower the jib in a minimum time of 10 seconds from top to bottom or vice versa.

An electric pump can be fitted in place of the rotary hand pump if required. Power can be supplied from batteries carried on the chassis charged during use if desired from an A.C. Mains charger.

GENERAL DATA

Chassis length (measured over 26 inch wheels) 90 inch (2,20 m)

Chassis width 40 in. (1,0 m)

Length overall (jib in lowest position) 124 in. (2,95 m)

Height of camera head mounting platform (low range)

Minimum 1 ft 3 in. (38cm)

Maximum 6 ft 5 in. (195cm)

Height of camera head mounting platform (high range)

Minimum 1 ft 10 in. (55 cm)

Maximum 7 ft 0 in. (213 cm)

Weights (estimated)

Chassis (with front wheels and pump unit) 315 lb (143,0 kg)

Steering Assembly 160 lb (72,6 kg)

Jib Assembly 134 lb (60,8 kg)

Platform Assembly 120 lb (54,5 kg)

Total weight (without head) 729 lb (331,0 kg)